What are planetary gears?

Planetary gears are a special type of reducer that is often used in combination with stepper motors to improve the performance and functionality of these motors. These reducers got their name from their characteristic arrangement of gears that resembles the arrangement of the planets around the sun.

Advantages of planetary gears ?

Planetary reducers offer several advantages over other types of reducers, including high torque, high positioning accuracy, compact design, and minimal vibration.

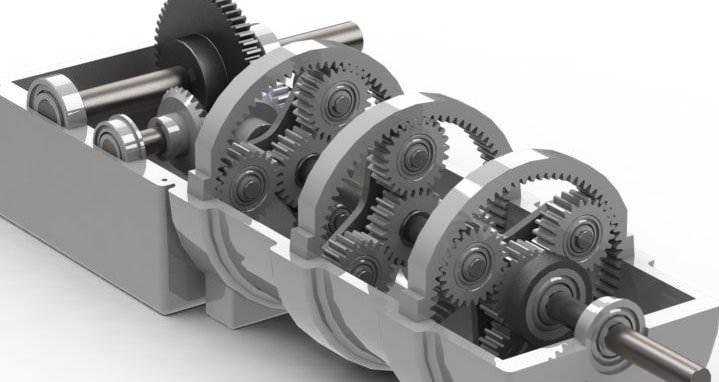

What does a planetary gear reducer consist of ?

1. Sun/central gear

The central gear is located in the middle of the reducer. It is connected to the input shaft and drives the planetary gears.

2. Planetary gears

Several smaller gears (planets) that are located around the central gear. Planetary gears are connected to the inner ring and rotate around the central gear.

3. Inner ring

A fixed external gear that holds the planetary gears in place. The transmission of torque from the planetary gears to the output shaft takes place via the inner ring.

4. Output shaft

The output part of the reducer that receives the torque from the planetary gears via the inner ring. This output torque is further transmitted to the working part of the machine.

5. Housing

The external assembly that holds all parts of the reducer together and provides protection from external influences and enables the proper operation of the planetary reducer.

Specifications of our planetary gear motors:

| Torque | 11 nm |

| Voltage | 12 V |

| Speed | 5 s/min |

| Shaft length | 30 mm |

| Dimensions | Ø48×195 mm |

| Max. loading, turning the spit | 80 kg |